DETECTION METHODS

DIRECT EXAMINATION

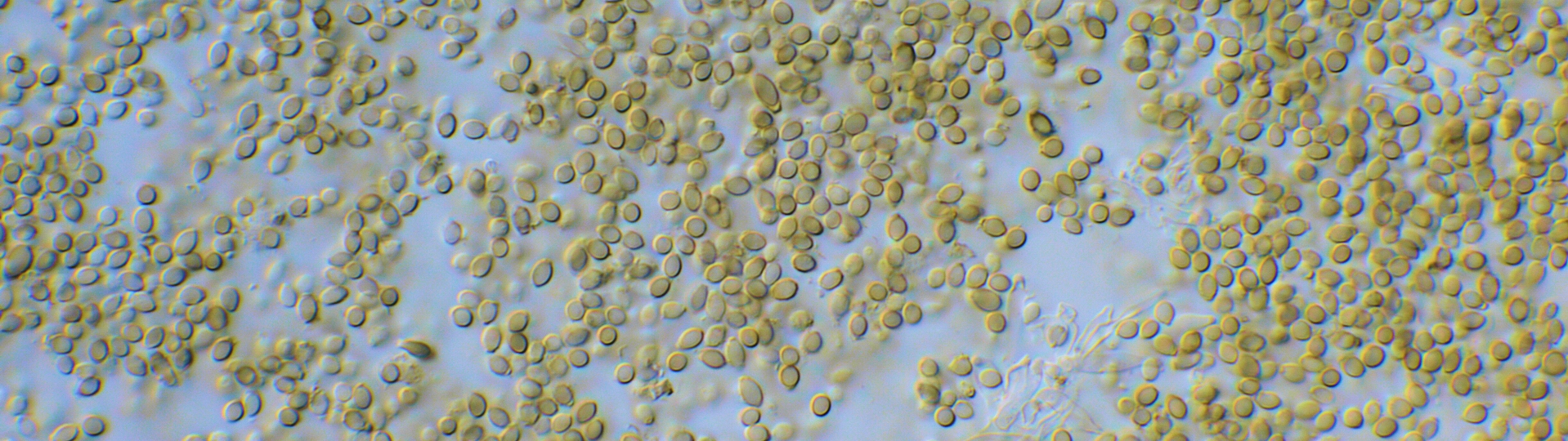

In foods spoiled by fungi it is often possible to observe the responsible fungal growth directly by the naked eye and/or by observation in a stereomicroscope. This is due to the size of the fungal colony and that fungal growth normally takes place on the surface of the product. However, the observation has to be made immediately after growth has taken place, since any handling of the product is bound to remove the visual appearance of the fungi. If fungal growth is expected, it is always recommended to examine the food products by microscopy. Slides can be prepared by placing a small part or volume in a mounting medium (Fig. 323). Preparations with the aid of sellotape can also be helpful (see Fig. 324). When fungal growth has been detected by direct examination, the fungus is streak-inoculated onto an appropriate medium. This is preferably done while examining the contaminated sample in a dissecting microscope.

DIRECT PLATING WITHOUT SURFACE DISINFECTION

Direct plating without any treatment is considered to be an effective technique for mycological examination of all foods. For foods such as grains and nuts, a sample size of 100 units is plated, whereas a lower number of pieces (e.g. 1 × 1 cm) of other products (e.g. fruits, vegetables) are cut out and transferred to appropriate media. In some cases a surface disinfection before direct plating is considered essential to remove the fungal spores on the surface, thus permitting enumeration of fungi actually invading the food (see below). In cases where surface contaminants become part of the downstream mycobiota, e.g. wheat grains to be used in flour manufacture, grains should be investigated both with and without surface disinfection. If visible fungal growth is present on the material, then small pieces of fungal material can be plated directly onto agar media (see Fig. 325).

Plating: Transfer food particles (e.g. 100 grains or 25–50 pieces of other products) with a sterile forceps onto previously poured and set plates, at the rate of 5–10 particles per plate.

Incubation: The standard incubation regime for general-purpose enumerations is 25 °C for 5 days. Plates should be incubated upright. The plates can be kept in perforated plastic bags to minimise evaporation. The perforation of the plastic bags, combined with a forced airflow through the incubator is necessary to maintain the initial composition of the atmosphere in contact with the plates. It has been shown that accumulation of CO2 significantly influences the growth of fungi.

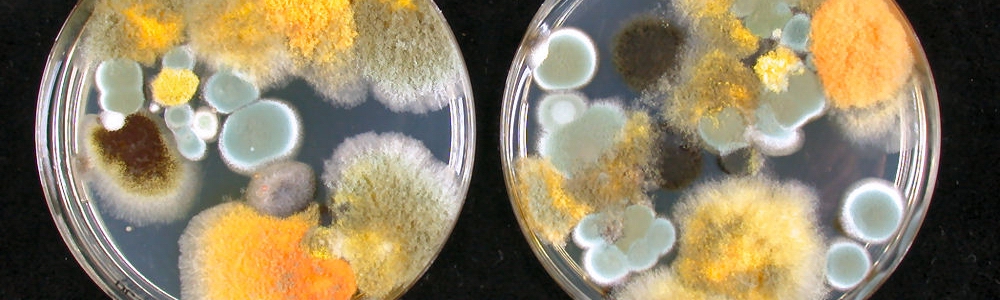

Results: Express results as percentage of particles infected by fungi. Differential counting of a variety of genera and sometimes even species is possible using a dissecting microscope.

DIRECT PLATING WITH SURFACE DISINFECTION

For foods such as grains and nuts, a surface disinfection before direct plating is in most situations considered essential to remove the fungal spores on the surface, thus permitting enumeration of fungi actually invading the food. An exception is to be made for cases where surface contaminants become part of the downstream mycobiota, e.g. wheat grains to be used in flour manufacture. In such cases grains should be investigated both with and without surface disinfection (see below).

Wash: 40 g of grains in 360 ml sterile 0.1 % peptone. Analyse the wash water by dilution plating to get the surface contamination by itself (see below).

Surface disinfection: Food particles are surface disinfected by vigorous shaking in 0.4 % freshly prepared chlorine (household bleach, diluted 1:10) for 2 minutes. A minimum of 100 particles should be disinfected and plated on each chosen medium. The chlorine should only be used once.

Rinse: After pouring off the chlorine solution, rinse once in sterile distilled or deionised water.

Plating: As quickly as possible, transfer 100 food particles with a sterile forceps to previously poured and set plates, at the rate of 5–10 particles per plate.

Incubation: The standard incubation regime for general-purpose enumerations is 25 °C for 5 days. Plates should be incubated upright. The plates can be kept in perforated plastic bags to minimise evaporation. The perforation of the plastic bags, combined with a forced airflow through the incubator is necessary to maintain the initial composition of the atmosphere in contact with the plates. It has been shown that accumulation of CO2 significantly influences the growth of fungi.

Results: Express results as percentage of particles infected by fungi. Differential counting of a variety of genera and sometimes even species is possible using a stereomicroscope.

DILUTION PLATING

It is important to note that it is difficult to quantify the fungal biomass including hyphae, spores and other propagules. Fungi, unlike bacteria and yeasts, do not grow as single cells, but as a mixture of hyphal fragments and other fungal cells. Some richly sporulating species are more dominant (and over representative) than poorly or non- sporulating species.

Sample size: A sample as large as possible should be used. We normally recommend 5 g samples for homo-geneous food materials (e.g. flour) and 40 g samples for non-homogeneous food materials (e.g. grains).

Initial dilution: The initial dilution should be ten-fold (1 + 9) i.e. 5 g samples in 45 ml or 40 g samples in 360 ml in water with 0.1 % peptone.

Soaking: Dried samples, where the fungi are deep seated or internal (e.g. as in grains and nuts), should be soaked for 30 minutes in 0.1 % peptone solution at room temperature before homogenisation. For powders and other homogeneous samples, no soaking is required.

Homogenisation: The use of a Stomacher or equivalent bag mixer for 2 minutes is preferred. If the food material is tough, a blender may be used with a 60 sec. blending time.

Further dilutions: Standard ten-fold dilutions 1 ml + 9 ml 0.1 % peptone are recommended. An alternative is five-fold dilutions 1 ml + 4 ml 0.1 % peptone, which is useful when small concentrations of fungi are present. Normally a maximum dilution of 10-3 (i.e. two dilution steps after homogenisation) is sufficient, however, if the food has been in contact with soil a maximum dilution of 10-5 may be necessary.

Plating: Spread plates are recommended over pour plates. Inocula should be 0.1 ml per plate, spread with a sterile Drigalsky spatula (bent glass rod). Triplicate plates at each dilution step should be plated.

Incubation: The standard incubation regime for general purpose enumerations is 25 °C for 5 days. Plates should be incubated upright.

Results: Across all dilutions all colonies should be counted on plates with up to 30–50 colonies. Differential counting of a variety of genera and sometimes even species is possible using a stereomicroscope. The result is calculated as colony forming unit (CFU) per gram sample, using the formula: CFU/g = (Sum of colonies on all dilutions)/(Sum of amounts of product spread on the plates counted expressed in grams).

Note that the spread of 0.1 ml onto the plate is equal to a 10-fold dilution.

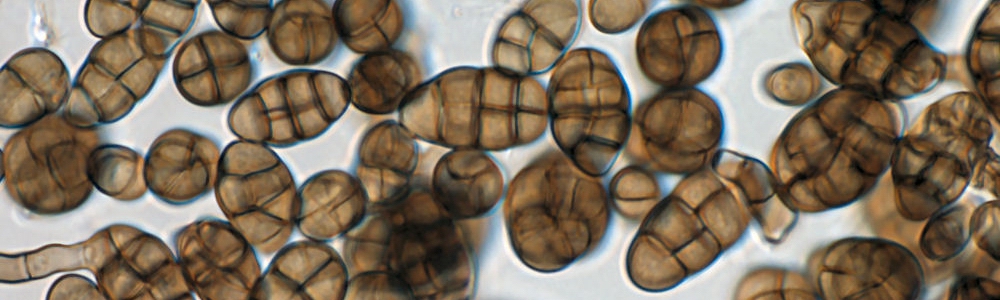

Detection of heat resistAnt fungi

By definition, a heat resistant fungus produces propagules that can survive a heat treatment for at least 30 minutes at 75 °C. These propagules are often ascospores, but also structures like sclerotia, chlamydospores and thick walled hyphae are able to withstand higher temperatures. Species belonging to the genera Paecilomyces (with byssochlamys-morph), Aspergillus (with neosartorya-morph) and Talaromyces have been most frequently isolated from spoiled pasteurized products. Ascospores of the genera Penicillium (eupenicillum-morph), Aspergillus (with emericella-morph), Hamigera, Thermoascus, Rasamsonia and Monascus are less commonly occurring. A crucial step in the procedure is the identification of the fungi to species level. Since aerial contamination is one of the main problems during this procedure, false positive results can be obtained. Therefore identification to species level will reveal if the isolated fungi are known to be heat-resistant. The methods described below should not be applied to products which have already had a heat treatment/pasteurization step, since this is often sufficient to activate the ascospores. If the product has already been heat treated, use one of the isolation methods described in this manual.

Raw materials, especially those that have been contaminated with soil, are likely to contain heat resistant fungi. Well-known examples are fruits and fruit concentrates, pectin and raw milk. Two most commonly used detection methods are described in this chapter, the Petri dish method and the filtration method. The Petri dish method is recommended for solid and non-filterable samples (e.g. pectin, concentrates), while the filter method can be used for the heat resistant moulds in clear filterable liquids such as liquid sweeteners, water samples, flavourings, etc. as well as powders soluble in water.

PETRI DISH METHOD

The Petri dish method is divided in seven steps as shown in the flow-sheet in Fig. 326. Since heat resistant fungi are often present in low numbers in the sample, it is recommended to analyse a larger volume than recommended for other food products.

Sample preparation: For products not listed in the flow sheet it is recommended to analyse at least 100 grams. Water should be added until a final volume of 500 ml is obtained. For very acid juices or concentrates, the pH should be adjusted to 3.5–4.0.

Homogenization: Polyethylene Stomacher bags are preferred instead of bottles, since the heat transport in the bags is faster. After homogenization for 2 minutes, the Stomacher bag should be sealed properly, with no air present.

Heat the Stomacher bag with the content in a water-bath for 30 minutes at 75 °C. The Stomacher bag should be placed in a horizontal position and totally submerged in the water. The time frame starts when the whole sample has reached at temperature of 75 °C. This might take at least 5–10 minutes (depending on the sample).

After the heat treatment, the sample should be cooled rapidly to 55 °C.

Disinfect the Stomacher bag with 70 % ethanol and transfer the sample into a sterile bottle. Add an equal volume of hand warm double strength Malt Extract Agar to the sample. If heat resistant bacteria (Bacillus spp.) are expected, it is also necessary to add the antibiotic chloramphenicol to a final concentration of 100 mg per litre.

Mix thoroughly and disperse the entire sample over 150 mm Petri dishes. The mixing and pouring of the Petri dishes should be done in a laminar flow cabinet to prevent contamination from the air.

Place the Petri dishes in an upright position in the incubator and incubate for at least 14 days at 28–30 °C. The plates should be examined for fungal growth after 7 and 14 days and visible colonies are usually seen after 7 days of incubation. If fungal growth is present, then isolations on Oatmeal agar should be made.

FILTRATION METHOD

Samples that can be filtered can be analysed using this method, as well as the rinse from PET bottles and other packaging. The filtration method includes the following steps:

Take at least two samples of 50 g each after vigorously shaking and add the samples to two bottles containing 100 mL sterile 0.1% aqueous peptone buffer; mix well to dissolve.

Filter both samples sequentially through the same sterile 0.45 µm membrane filter and rinse the interior of the funnel three times with 20–30 ml of sterile diluent.

Aseptically transfer the filter in a small sterile sample bag with 10 mL of sterile diluent. The filters are analysed as described above (under Petri dish method) following step 3 onwards.